The two core material technologies used in almost all cables are fiber optic, and copper wiring. Whether you’re looking at an HDMI cable, a USB cable, Ethernet patch cable, or any other kind of network of data transmission cabling, they are all built using copper or fiber optic internal wiring.

Fiber optic tends to be the more premium solution, while copper wiring is far more common, but why is that? What are the differences between these two cable types, and why might you want to pick one over the other?

Here’s everything you need to know about fiber vs. copper cables, to help you pick the right cable for your needs.

The Differences Between Fiber and Copper

Fiber optic and copper cables are built with very different materials, and as such are used in different circumstances for different tasks.

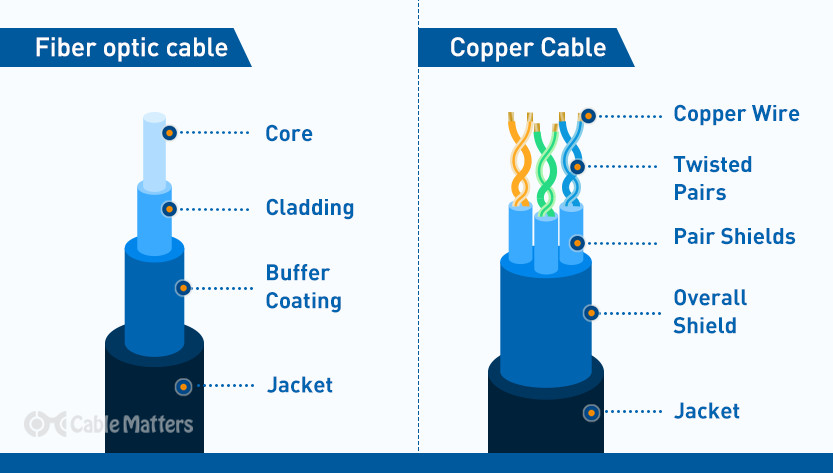

Fiber optic cables are built with a silica glass fiber core, about the width of a human hair. It transmits data via light, by allowing it to bounce back and forth down the length of the glass core, while a glass cladding surrounds the core and ensures the light is retained within it. This is then wrapped with additional insulating material, including a layer of plastic to strengthen the core, followed by a layer of gel-filled sleeving or kevlar (depending on the manufacturer) and then a layer of colored plastic to identify the fiber optic cable type.

The outer layers also deliver a measure of fire resistance, as well as dictate whether the cable is rated for running behind walls, or not.

Copper cables have a core of copper wiring, though come in a few different types. There are solid copper core cables, like coaxial cables, which are then covered by multiple insulating and protective layers, and twisted pair copper cables, which have between one to four pairs of insulated copper wiring that are twisted together in pairs and then enclosed within various protective and insulating layers.

The specific configuration of the copper cables is dependent on their intended use, but the ultimate design is the same: a copper core, surrounded by insulating and protective coatings. Some will also include additional strengthening measures like splines.

You’ll find copper and fiber optic cable options for all sorts of cable types, but in all cases fiber optic cables are the more premium solution. They offer greater performance, with much higher data rate ceiling than copper – several hundred times higher in some cases; they support greater cable lengths; they’re more reliable, being less susceptible to electromagnetic interference (EMI); they’re more durable, with a much greater pressure resistance than copper cables, and they’re harder to snoop on too, with any compromise of the cabling easily detectable.

If you’re trying to pick between fiber vs. copper cables, then you’ll want to factor cost too, (fiber optic cables are typically more expensive) but from almost any other perspective, fiber cables are the clear winner.

Advantages of Copper Cable

In the fiber vs copper cables head to head, there aren’t many metrics that copper comes out on top. It’s not going to win a face off on performance, distance, resistance to EMI, or physical durability, but there are some areas where copper still holds a significant advantage.

The first is cost. While the price per foot of fiber optic cabling has come down significantly over the years, copper wiring is still the cheaper solution. Part of that is the reduced cost of the cabling itself, but a greater part plays in to copper cabling’s other great strength: existing infrastructure.

Fiber optic cable is seeing increased usage in all manner of digital infrastructure, but the majority of what already exists, especially when involving legacy networks and systems, is still copper cabling. With additional costs involved in replacing even outdated or failed copper cables with fiber optic, and even greater costs and complexity when trying to run copper and fiber optic cables as part of the same network, running pure copper cabling can often be the cheaper solution.

Long term, the fiber vs copper cable debate will be easily won by fiber, but there is always likely to be a place for affordable copper cables.

Advantages of Fiber Optic Cable

Fiber optic cables are a superior cable solution to copper in almost every way. For starters, the performance, or maximum data rate they can support is so much greater than anything copper cables can achieve. Where copper cables are limited to around 10 Gigabits per second in the absolute best case scenario, fiber optic cables can manage as much as 60 terabits per second, theoretically. While in reality that figure is more realistic and viable for existing network equipment, it’s still possible to get hold of fiber optic network patch cables that can handle 100 Gibabit network speeds.

When it comes to fiber vs copper cable lengths, too, fiber optic holds a significant advantage. While individual copper cables have a maximum range of around 330 feet, some fiber optic cables can carry data up to 25 miles. That is only the most capable of single mode fiber optic cables but even more affordable and typical multimode fiber optic cables can manage 1000 feet per cable.

For more information on fiber optic cable types, read out complete guide.

Despite being made of glass, fiber optic cables are more durable than their copper counterparts too. Standard fiber optic cables can withstand a pulling force of up to 50 lbs, while the most sturdy of them can manage a pulling force of up to 200 pounds. The maximum rating for a standard copper patch cable is a mere 25 pounds, making fiber optic cables far less likely to experience wear and tear during deployment, or if there is any significant stress placed on the cable.

That added durability plays into fiber optic cable longevity, too. Where copper cabling needs to be replaced every five year so due to degradation – and can degrade to the point of complete signal loss if ignored – fiber optic cables can last far longer, with many not needing to be replaced for up to 50 years in ideal conditions.

Even when copper cabling isn’t failing due to degraded wiring, they can also fail due to interference, as copper cables are susceptible to electromagnetic interference; fiber optic cables are not. Although quality copper patch cables from manufactures like Cable Matters employ robust shielding to help prevent EMI affecting copper cable signal quality, interference can occur on cheaper cables, especially older standards like Cat 5 Ethernet cabling, which weren’t designed with additional shielding in mind.

Fiber optic cables are more resistant to deliberate interference, too. Where copper cables can be ‘tapped’ by connecting to the electrically transmitting wire, fiber optics can’t be tapped into in the same way. Any attempts to do so can be quickly detected by the network, too, allowing administrators to shut down that cabling and investigate any potential breaches.

On a cost front, fiber optic is the more expensive solution generally, however, long term it can actually be the more cost effective solution. Due to fiber optic cables being able to run so much longer than their copper counterparts, you have to install far fewer distributed cabinets to repeat the signal over longer distances. The lack of any need for additional EMI shielding or fire protections, can help keep costs down too.

With an eye to the future, where most networks will be built on fiber optic technology, it doesn’t necessarily make much sense to install copper cabling which will be outdated and require replacement in the future, where a fiber optic network would be scalable and less in-need or maintenance over the ensuing years.

Fiber Optic vs Copper Cables: Selecting the Right Cable for Your Needs

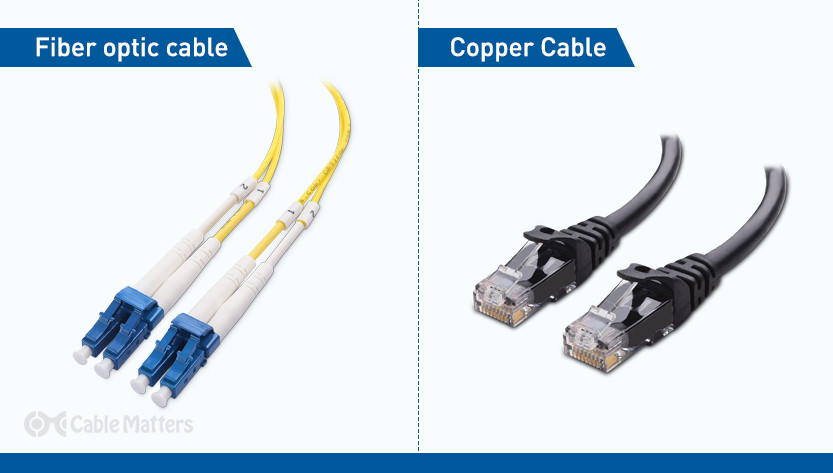

As much as the fiber vs. copper cable debate may seem settled at this point, that’s not to say that copper cables can’t still be useful. If you’re building a home network, or any network where the necessary speeds aren’t greater than 10 Gigabit per second, then copper patch cables are perfectly viable. You can even mitigate the problems with copper cable shielding by opting for a modern design, like a Cat 6a cable, which features capable shielding and can also have additional durability through a reinforcing spline.

Fiber optic cables are the superior solution for longer network cables, however, especially if they need to be run through walls, or buried under the ground, and when building network infrastructure where the ability to transfer masses of data to a number of individual systems at a time is important.

If you’re building an A/V setup that needs a long video transmission cable, too, you’ll want to use an active HDMI cable. Those are fiber optic and deliver the kind of performance necessary for high-bandwidth data delivery over distances that passive copper HDMI cables just can’t manage.