Gold isn’t just a precious metal, it’s a highly versatile material for use in all sorts of manufacturing processes. One of the most important ones in the realm of cables, is in the connections at each end. Most cables are made with nickel-plated connectors, and that’s perfectly fine for everyday connections, but more premium cable designs use gold for a variety of reasons. Gold is an excellent electrical conductor, so it makes a great choice for crafting a reliable and effective connector. However, since budget cables use nickel plating instead, and silver is a viable alternative with some cabling, the question is often raised, does gold plating really make that much of a difference?

Cable connectors need to be robust, because they can be subject to lots of wear and tear over their lifespans. There’s friction from the port when they’re plugged in and unplugged, the potential for corrosion from the atmosphere – especially if it’s humid, and there’s physical damage from accidental drops, impacts, or compression to consider, too. Connectors also need to maintain structural integrity, so that they still fit their respective port, and maintain a strong and stable connection, even after years of use. Some cables even need to be able to help dissipate heat generated from high power transmission down the length of the cable, so thermal conductivity is almost as important as electrical conductivity.

Nickel connectors are good conductors and offer high corrosion resistance. It’s also a water-resistant material and is relatively affordable. Silver is a better conductor, though, and Gold is better at almost everything, with a higher conductivity and greater corrosion resistance. It’s just far more expensive.

Fortunately, there are ways around that. Making the entire connector out of gold or silver would be prohibitively expensive, and these metals lack the structural integrity of other metals which are more affordable and equally effective. Electroplating copper or aluminum with gold, silver, or indeed nickel, lets a connector enjoy its benefits without the higher material costs.

Cable Matters offers both gold-plated cables and nickel-plated cables. Although gold is the more premium material, it’s important to ask the question, is it worth the added cost? Which is ultimately better, gold, silver, or nickel-plated connectors? Let’s dive into each to find out which.

What Are Gold-Plated Connectors?

Gold-plated connectors are connectors which have been gold-plated. That might sound a little facetious, but this is one of those situations where the name is quite literal. It works in the same way as gold-plated jewelry. It lets the manufacturer create something that has all the properties of gold on the outside, whilst letting them create the item for far less by using a cheaper metal on the inside.

As one of the most electrically conductive materials we know of, gold would make for a great material to create all sorts of connectors from, if it was stronger and cheaper. Instead, gold is plated onto copper or aluminum connectors in a thin layer, providing excellent conductivity for the signal, without making the cable prohibitively expensive.

But copper is a better electrical conductor than gold, so why bother coating it? The main answer is oxidation. When exposed, copper has a tendency to break down, and is not very resistant to corrosion. That’s where the gold plating really shines, because gold is not only a strong conductor, but it’s also highly resistant to corrosion and oxidation from the environment. This makes gold-plated connectors not only great for everyday use in any situation, but particularly useful in environments that have a more corrosive atmosphere, such as when the environment experiences high humidity or is regularly exposed to corrosive salts and acids.

Gold is also an excellent thermal conductor, making it a great solution for connector plating in more thermally demanding environments, or when the cable is designed to carry a heavy power charge, since it will help dissipate any excess heat more easily. It retains its high electrical conductivity at high temperatures, too, so it can be relied upon to retain a connection even when the environment is more demanding.

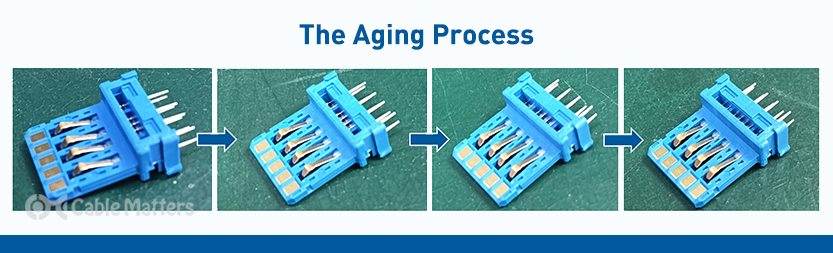

One potential downside to using gold-plated connectors is that gold is not particularly hardy. This can be a problem with repeated plugging and unplugging, or if the cable connector was to receive direct impact damage. This is mitigated in most cases by using an alloy of gold for the plating, including nickel or other metals to increase its hardness by several magnitudes. That makes a gold-plated connector much more durable against all kinds of damage.

One final advantage of gold-plated connectors is that gold is not magnetic. That makes gold-plated connectors suitable for use in environments where heavy magnetism is present, such as in medical equipment like MRI scanners.

Before gold plating a connector, manufacturers typically add a layer of underplating metal, usually copper, electrolytic nickel, or electroless nickel. This provides a firmer structure for the gold plating to adhere to, as well as adding an additional anti-corrosion layer. Just as it prevents corrosion seeping in, though, this underplated layer also prevents the diffusion of elements such as zinc, from the inner substrate layer into the precious metal, which would compromise its abilities.

Do You Need Gold-Plated Connectors?

As much as gold-plated connectors offer a number of advantages over other connector materials, do you really need gold-plated connectors? The answer, is that it depends.

Nickel-plated connectors are far more common than gold because they offer a good-enough connector at a lower price. They are conductive enough to make sure the data is transmitted without any obvious degradation, and they offer reasonable protection against corrosion. However, gold-plated connectors are much more effective, delivering better protection against the elements, particularly oxidation, making them a much better choice in more corrosive environments, such as high salt or humidity.

Silver-plated connectors are an option too, and they are actually the best choice when it comes to thermal and electrical conductivity – even beating out the “gold standard,” for conductivity, copper. They are, however, more expensive than nickel-plated connectors, and not quite as corrosion-resistant as gold.

So no, you don’t need gold-plated connectors on your cables as there are perfectly viable options in the form of nickel and silver-plated connectors. But how do you know which is the right type of connector for your needs? Let’s take a look at how these different types of connectors compare.

Gold vs. Silver vs. Nickel-Plated Connectors

Gold, silver, and nickel are excellent solutions for plating connectors, but which is better? There are advantages and disadvantages to each that may make one of them a better choice for you the next time you upgrade your cabling.

Nickel plating is the industry standard, in that it’s the most prevalent on modern cabling. It’s cheaper than both silver and gold plating, making it more attractive for budget cable offerings and for larger purchase orders where many tens or even hundreds of cables need replacing at once. However, cost is not the only factor to consider with such cables, and nickel is not the best at protecting your data or the structure of the cable itself.

Nickel plating offers a high corrosion resistance against typical environmental factors, but it falls far behind gold when it comes to protecting your cables against high salt, acid, or humidity environments. This is particularly important to consider if you expect to reseat the cable regularly, since the action and repeat exposure to the elements will wear down the cable connector faster without a gold-plated protective layer.

The biggest reason to avoid nickel, especially in professional environments, is that it’s nowhere near as conductive as the alternatives. At just 25% of the conductivity of copper, it’s less than half as conductive as gold, and less than a quarter of the conductive capabilities as silver. That may result in some slight signal loss which won’t necessarily be evident for everyday consumers, but professionals may wish to avoid this potential loss of data integrity.

Gold and silver are far more costly, but offer better conductivity and strong anti-corrosion protection – far stronger, in the case of gold. That ensures a quality signal down the cable, but also allows for high power transfer without risk of the cable connector being damaged through too great heat retention. Technically, silver is the better conductor of both thermal and electrical energy – it’s actually the best conductor of any known material, so it can be the better choice for a plated connector in some cases. However, as we discussed above, nickel can also have its place, especially when cost is a major factor.

Silver plating is far cheaper than gold plating, though. Gold is a very expensive metal – up to 80 times more expensive than silver. That makes silver plating connectors far, far more affordable when producing them at scale. Although a single cable connector plated in a thin layer of gold isn’t going to cost much, once you have tens of thousands of cables to manufacture, that cost adds up quickly. It’s especially true if your cable or device requires a thicker layer of anti-corrosion protection, or if the connector is particularly large.

Gold prices have also gone up dramatically over the past few decades as its use in electronics has ballooned. Today, gold is used in a wide range of electrical components – so much in fact you could melt down a couple of pounds of the stuff with just a few hundred old desktop computers. Silver, on the other hand, has remained comparatively steady. Although its price did increase dramatically in the early 2010s, it has since stabilized. Gold shows continued signs of growth, which may make it an even more expensive metallic plating material in the future.

Even with that more attractive pricing, though, silver isn’t the perfect solution. While it does offer fantastic anti-corrosion protection, silver does tarnish. It doesn’t oxidize under normal conditions, but it does form a range of sulfur compounds like silver sulfide. They don’t dramatically impact the anti-corrosion protections, nor the conductivity, but they do increase the contact resistance offered by the silver plating.

Fortunately, simply cleaning the connector, or plugging and unplugging it is usually enough to remove this layer of additional resistance, so active cables that have silver plating are unlikely to be particularly affected. However, static applications where a cable is plugged in and then left so, may benefit more from using gold-plated connectors, since they are less likely to tarnish in this manner. It’s also beneficial to use gold in low-voltage cables, since any additional resistance there is likely to impact the performance of the cable.

Conclusion

The question of gold vs. silver vs. nickel-plated connectors ultimately comes down to the planned use, budget, and the kind of environment the connector will be used in. If the environment is highly corrosive or high-humidity, and especially if the cable is expected to sit passively plugged in for longer periods of time, then gold-plated connectors do hold some advantage, even with their higher cost.

For more active scenarios, however, where corrosion is less likely, or if you’re looking to install or manufacture a large quantity of connectors, silver plating offers an equally-capable solution to gold plating, but at a much-reduced cost.

That’s for the situation as it stands in 2023, though. In the future, as the use of silver increases in electric vehicles and other devices, it may be that the increased cost of silver leads to greater use of gold plating in some scenarios, or a fall back on nickel for cost-saving purposes. At the very least, it’s likely to narrow that cost chasm between the two precious metals.

The gold vs. silver vs. nickel-plated connectors debate isn’t one that’s likely to be settled, but there are specific instances where one material is the better solution over the other. While gold, if not for its cost, would likely be the better material to use for its improved anti-corrosion protection and lack of tarnishing concerns, silver’s improved thermal and electrical conductivity can make it the ideal solution in specific use cases. For everything else, there’s nickel.